The heavy load!

It looks like we have another problem to solve! This work bag is sitting on the living room floor and really needs to be hung up somewhere.

The problem is this bag weighs a metaphorical ton! It has a laptop, an A4 diary, documents, some sample products and a few other items crammed in. Overall it weighs a little under 10Kg.

We have some offcuts of acrylic that can be formed into a hook shape but do not think it will be strong enough. We could make the hook and hope for the best, but if the hook won’t hold our overweight bag, there is a very high chance the laptop is going to get damaged as it crashes to the floor.

Acrylic hook render using SolidWorks

Luckily SolidWorks has some built in tools to help check that our material choice will hold the weight of the bag. It’s a simple model to create and it’s better to be safe than sorry.

The acrylic is 3mm thick, so lets create a 3D model of the hook in SolidWorks and input the material we intend to make it from. After adding some constraints, such as a fixed surface and the mass of the bag acting on the bottom face SolidWorks analyses the hook design. It shows we may have a problem (but we knew that already, acrylic is a very brittle material not known for its load-bearing capacity in bending).

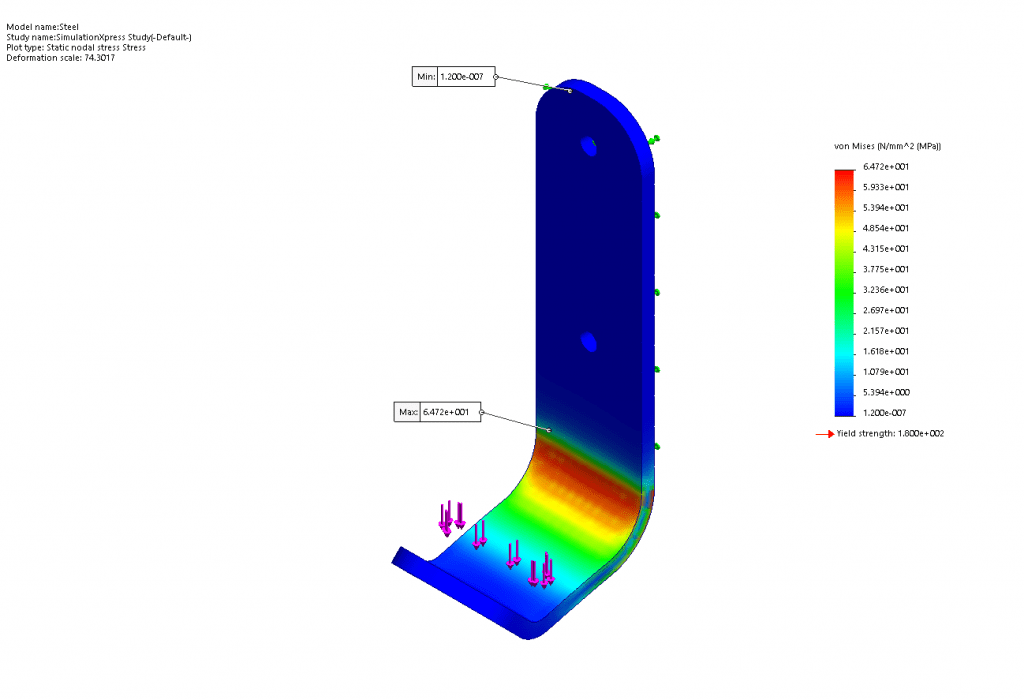

Analysis showing weight yields

The results show that the hook is going to yield under the weight of the bag (not really a surprise). In fact, the results tell us that the hook will be overloaded by around 50%.

The acrylic has a yield strength of 45MPa and the results show the hook will see stress of around 64MPa when the overly heavy bag is hung on it. Clearly, this is not going to be strong enough! We are going to have to see if we have a better material to make the hook out of.

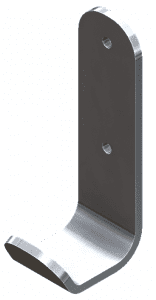

Render of a hook made from steel

After some digging around in the workshop we have an off-cut of 3mm hot rolled steel plate. Now this should be more than adequate to support our bag. Using the existing model of the hook and analysis for acrylic, we just need to change the material to steel and re-run the analysis.

We know from the results above the bag is going to cause around 64MPa of stress on the hook. SolidWorks confirms hot rolled mild steel has a yield stress of around 180MPa. Therefore, we can be confident this second material will be more than adequate to hold the bag. But let’s run the analysis to reinforce our confidence…

SolidWorks assessment gives confidence in the suitability of the material for the intended load

There we have it! If the hook is made from hot rolled mild steel, we have some confidence that it will be strong enough to hold the heavy bag. We can safely say that with a Factor Of Safety of around 2.8 if the bag drops to the floor, it will not be because the hook failed!

This little scenario is clearly made up for the purpose of this blog post. We knew the acrylic would not be strong enough to support our comically heavy bag. But it demonstrates the power of SolidWorks to assess the suitability of a given design in a few chosen materials. It also shows the value of getting such designs right before the costing stage of manufacturing in large volumes.

Please contact White Horse CAD for more information.

You must be logged in to post a comment.