July/August Stats

New Projects

Completed Projects

Outstanding Projects

So here we are in September!

It’s been a busy summer with plenty of jobs, hence rolling July and August updates into one newsletter. We continue to work with a range of clients to provide CAD expertise. It’s not an exhaustive list, but here goes – Agriculture, Automotive, Consumer Products, Construction, Electrical, Energy, IT, Medical Devices, Packaging, and Scientific.

Here’s some insight on some recent design work:

- Bespoke packaging

- Novel medical device

- Wearable consumer product

- Kitchen equipment

- Leisure equipment

White Horse CAD provides effective 2D and 3D design services for product design and development. We get projects completed, from single drawing updates to the complete design of complex components and assemblies.

Please get in touch if you’d like to find out more.

Happy Birthday!

On 15th August, White Horse CAD celebrated six years of trading.

On 15th August, White Horse CAD celebrated six years of trading.

This special date in 2017 was chosen as it also marked what would have been Tim’s mother’s 74th birthday & felt fitting for the business to be ‘born’ on the same day as her.

Thank you for your support; here’s to many more successes.

Trainee Success

Congratulations to Luke, our Trainee Engineer who’s recently completed a year at WHC.

Luke came to us having completed his Level 3 BTEC in Engineering. He’s shown great progress since joining WHC, completing many jobs and learning along the way, and is an asset to the team.

Testing the strength of 3D prints

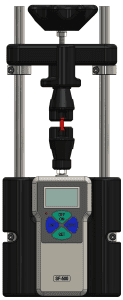

Tesiometer to test the strength of 3D prints

People often ask us how strong our 3D prints are, and we find it difficult to give them a quantifiable answer. So, we decided to design our own tensiometer to provide an answer to their question.

We invested in a relatively low-cost force gauge, metal bars, and collars. Then, we designed our tensiometer around the parts we had bought. Compared to most tensiometers on the market, our solution is rather basic. However, we can use the recorded failure load and some simple calculations to determine the ultimate tensile strength of the 3D-printed test piece. There are, of course, many variables that go into the strength of a 3D print. Still, by adding a few test pieces to each 3D print, we are building a database of results for different materials, colours, layer heights, print orientations, extrusion temperatures, and even machine make.

With a little bit of thought, some design time, and access to our own 3D printers, we can now start to quantify the strength of our in-house 3D printers. Over time, this will allow us to increase our understanding of 3D printing and perhaps increase the quality of the parts we deliver to our customers. It also doubles as an engaging, hands-on way to introduce our trainee to materials strength and testing.

For more information on 3D Printing, please visit our website.

What can White Horse CAD do for you?

If you’re new to White Horse CAD or just in need of a reminder, here are ten things we can do for you …

👍 Designs for new products and improving existing ones.

👍 3D CAD model from concept sketches.

👍 Photo-realistic renders & animations for product visualisations.

👍 CAD assemblies to evaluate how individual components interact.

👍 Production-ready engineering drawings for manufacturing.

👍 Advice on manufacturing options for your product.

👍 Design test fixtures to aid your production, verification, and validation process.

👍 Evaluate your product by printing a 3D prototype.

👍 Design special-purpose tooling and production equipment.

👍 Finite Element Analysis (FEA) to evaluate design suitability.

To discuss your projects, call the WHC office on 01373 801 803.

You must be logged in to post a comment.