We’re confident we can tick the boxes for your project

We’re happy to report another busy week of design work. We’re doing one of the things we do best; giving expert advice to create effective design solutions.

And what makes us so sure that we’ve got this right?

Well, it’s because we utilise our thirty plus years of hands-on engineering experience with cutting edge technology. It’s a winning combination that means we understand what clients need and the most cost-effective way to achieve this.

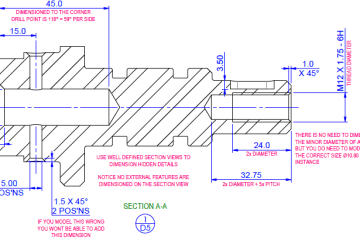

As a brief example…. One of our clients has an exciting brand-new idea for a consumer product. They are at the stage of needing the injection mould tool to start production. However, the cost they’ve been quoted is just too high to make this a profitable venture. If they can overcome this, the cost of production is low and straightforward.

So, we are accompanying the client at their request to visit the injection mould tooling company. They are keen for our input to help overcome this barrier. The injection moulding tool is a crucial and often the most expensive part of the manufacturing process. Even the smallest of changes to the mould can be very costly as well as a drain on time. Both of which you obviously want to avoid when you’re heading towards getting ready to market your product.

Start a conversation with us

So it’s essential to get the design right, the first time. Our task is to review and modify the design that can be optimised for injection moulding as well as being fit for purpose. If you’d like to find out more about us, please visit the White Horse CAD website. Or we always welcome a call if you’d prefer on 01373 801 803.

For the time being, we can’t reveal anymore due to our confidential agreements but hope this product will be one for our portfolio of case studies in the future. Please keep an eye out for these and if you’re in need of an effective solution to a design problem, do get in touch. We’re confident we can help.

You must be logged in to post a comment.