In this week’s news, you may have read that a baby’s life was saved by surgeons who could visualise and prepare for mending her broken skull with 3D printed replica. Using scans of the baby’s head, a replica model was created ahead of the surgery. We think you’ll agree this is a wonderful example of how 3D printing can bring maximum success.

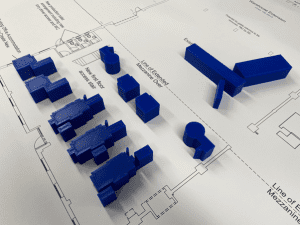

3D Prints on a blueprint showing floor layout. Perfect for planners and architects.

With experience in the orthopedic industry, we are familiar with producing 3D-printed replica bones. The models play a vital role in the design and development of medical devices by providing a realistic substitute for real bones. As well as bones, our 3D printing is useful for models in architecture, parts, and cases for mechanical parts and consumer products. Others have used the models in their marketing material for clients.

The benefits of 3D printing include:

Design Validation– 3D models help to evaluate designs and highlight any refinements. Using the models during the design development phase can save money and time by ensuring the design is correct before the costly manufacturing process. Depending on the complexity and size of the model, 3D prints can be created within hours. And we all know time can be of the essence when working on tight deadlines!

Quality – We have our 3D printers in-house, meaning we can advise on which suits your design best. How the printers create the models in layers helps to provide quality in various materials and finishes.

Prototyping – 3D printing brings a design to life. Physically holding the model or part can help with the kinesthesis and visualise the final product. Using the prototype, you can test fit, form, and function and gain important user feedback.

3D printed bones

Could your project benefit from a 3D print? To learn more about our 3D printing services, please visit the White Horse CAD website or call 01373 801 803.

You must be logged in to post a comment.