If you are an artisan, crafter or maker White horse CAD can help you turn your ideas into products.

Sketch to CAD

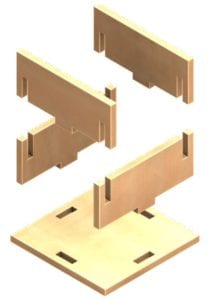

White Horse CAD can take your sketches, line drawings, or photos and turn them into 2D or 3D geometry that can be read by cutting machines such as lasers or CNC’s. From the sweeping curve of a hand-crafted metal blade through to interlocking pieces of wood, metal, plastic, card, or any other material you can think of.

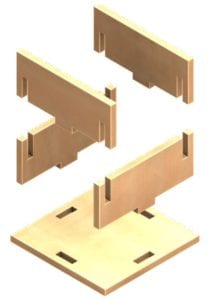

Check parts before cutting material

If you are working with expensive materials or planning on ordering a big batch of parts from a supplier. You need to know that the parts are going to fit together and interact as you intend them to. We can turn your ideas into 3D cad models and create assemblies to check parts fit together, or move as they should. A few checks early in the design can save you hundreds of pounds in wasted time and materials.

Reduce waste

If you are working with expensive materials or planning on ordering a big batch of parts from a supplier. You need to know that the parts are going to fit together and interact as you intend them to. We can turn your ideas into 3D cad models and create assemblies to check parts fit together, or move as they should. A few checks early in the design can save you hundreds of pounds in wasted time and materials.

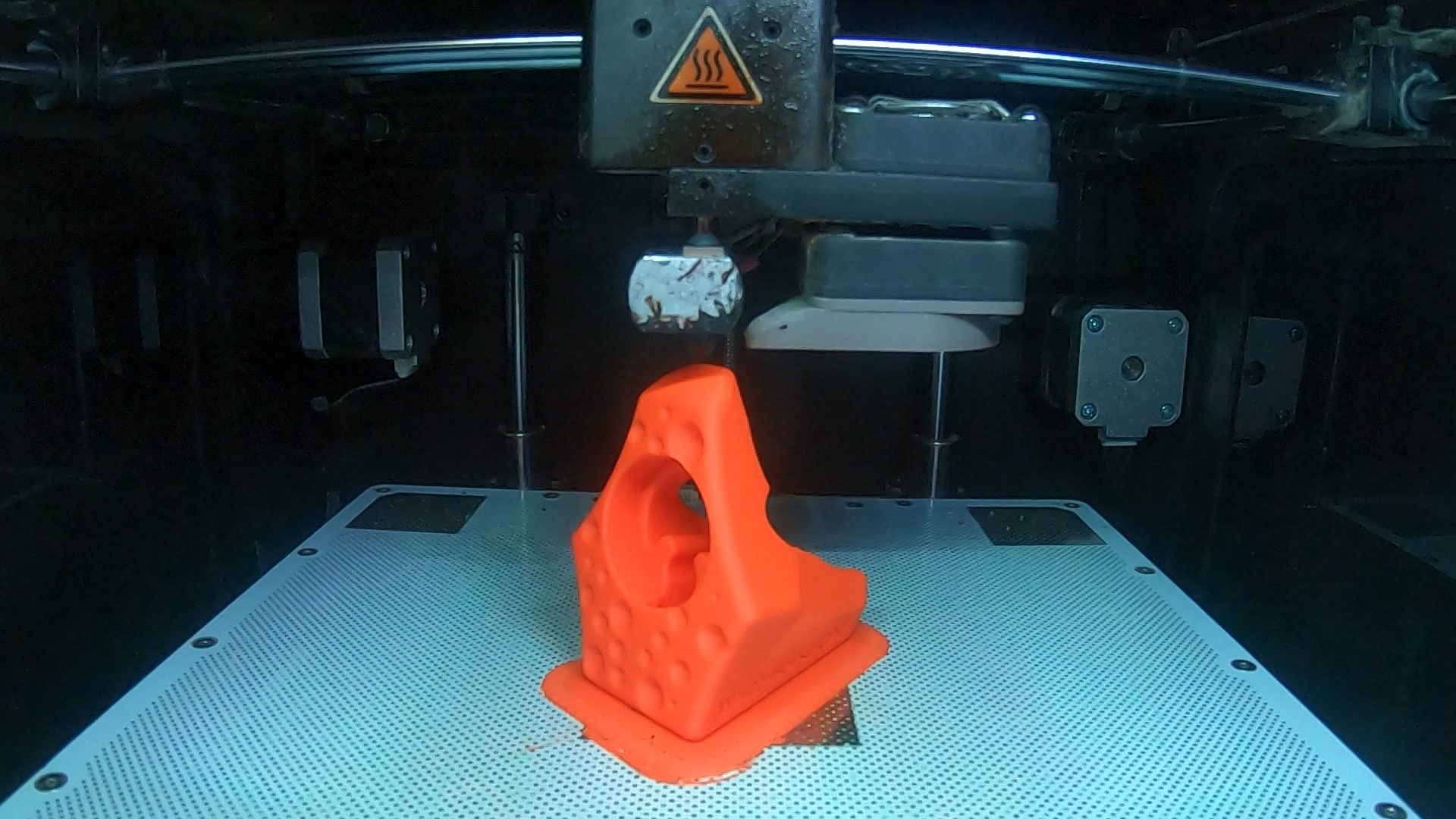

3D Printed Parts

If you need a plastic slider bearing, a bespoke knob, or even a jig to help you assemble or drill your pieces. White horse CAD can help with not only the design of the part but also with 3D printing of the parts as well.

know more please send us an email or give us a call.

Want to be the first to read our news?… sign up here…

Related

Sketch to CAD

Sketch to CAD Check parts before cutting material

Check parts before cutting material 3D Printed Parts

3D Printed Parts

You must be logged in to post a comment.