Photo realistic render with bronze finish

Sometimes I feel the need to indulge in some engineering-based fun. I am lucky enough to have access to loads of very cool software, gadgets and machines. So when I started working on some new Phi related marketing images for the White Horse CAD Limited’s website I thought to myself. I have always wanted a Fibonacci Gauge, but I could never justify the cost, the cheapest I could find was close to £40. So, I decided, I can design and make my own set, with what I had to hand.

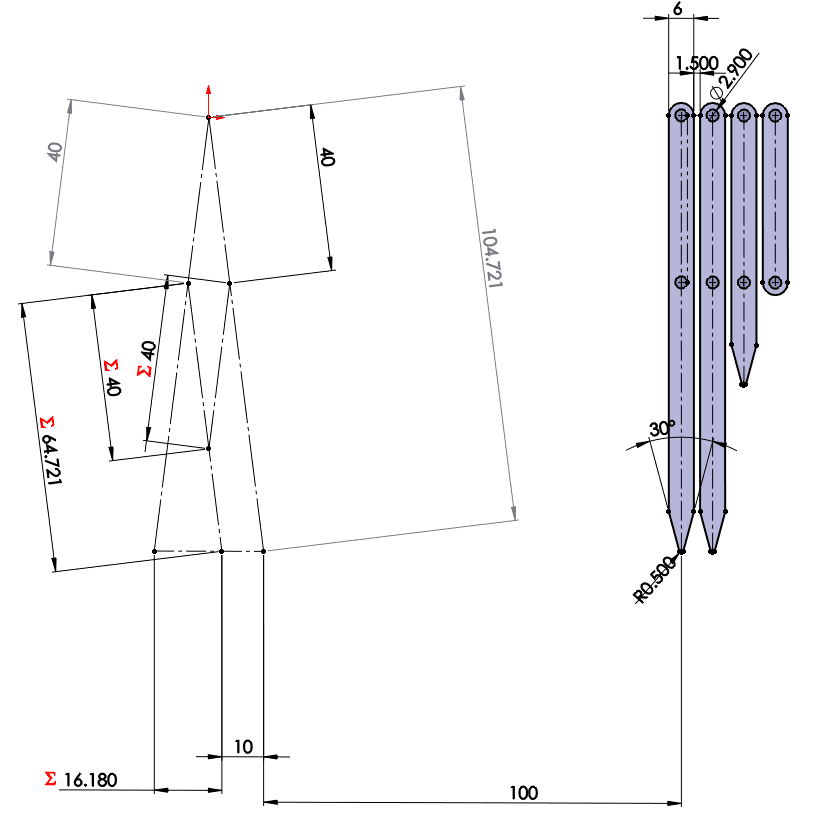

An equation driven sketch produced in SolidWorks

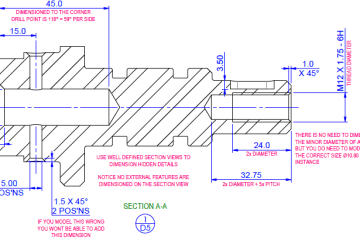

Starting in SolidWorks I created an equation driven sketch that allowed me to model the 4 main components that make up the gauge. The sketch was configured so that all of the components were laid out ready for cutting on a CO2 laser cutter.

The only thing I didn’t have to complete the project were some M3 nuts. But that was not going to stop me… Back to SolidWorks to model some thumb nuts that could be 3D printed while the 4 wooden parts were being laser cut and sanded. With all of the components made I only had to assemble and test my latest design. Luckily I already had a Fibonacci curve modeled so I could check the gauge worked as intended.

This was a fun little project that demonstrates how SolidWorks uses parametric equation driven sketches to create simple mechanisms. If you would like to know more or have an unmet product development need that you would like to discuss with us please contact us.

You must be logged in to post a comment.