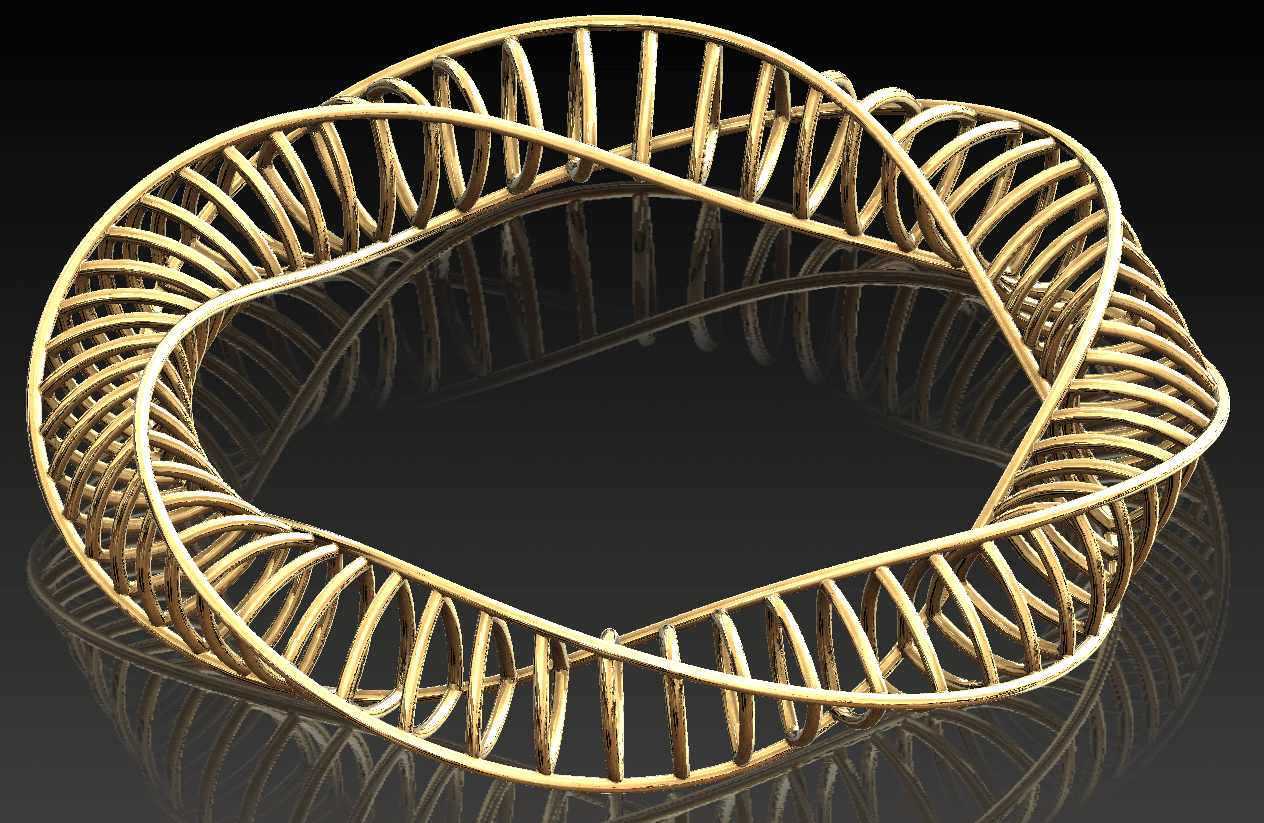

A bangle rendered with gold

While White Horse CAD specialise in engineering services, we also work with many non-engineering industries.

For example, we create complex CAD models for jewellery design, hand-made craft products, or even architectural and interior designs.

The product on the left is a double twist open structured mobius bangle. It’s rendered in solid gold. The creation of complex geometry is important in many industries. The bangle design can reduce material volume allowing for more cost-effective 3D printing in precious or semi-precious materials like titanium and silver.

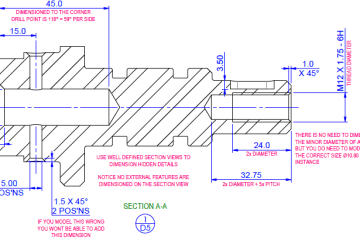

White Horse CAD also has extensive experience designing products for laser cutting. We use parametric CAD models to create 2D files to interface directly with many 2D machines, including laser cutters. Using parametric models allows us to generate many iterations for different material thicknesses. Models are especially important when close fits on sheet materials with wide thickness tolerances are required, such as wood and cast acrylic.

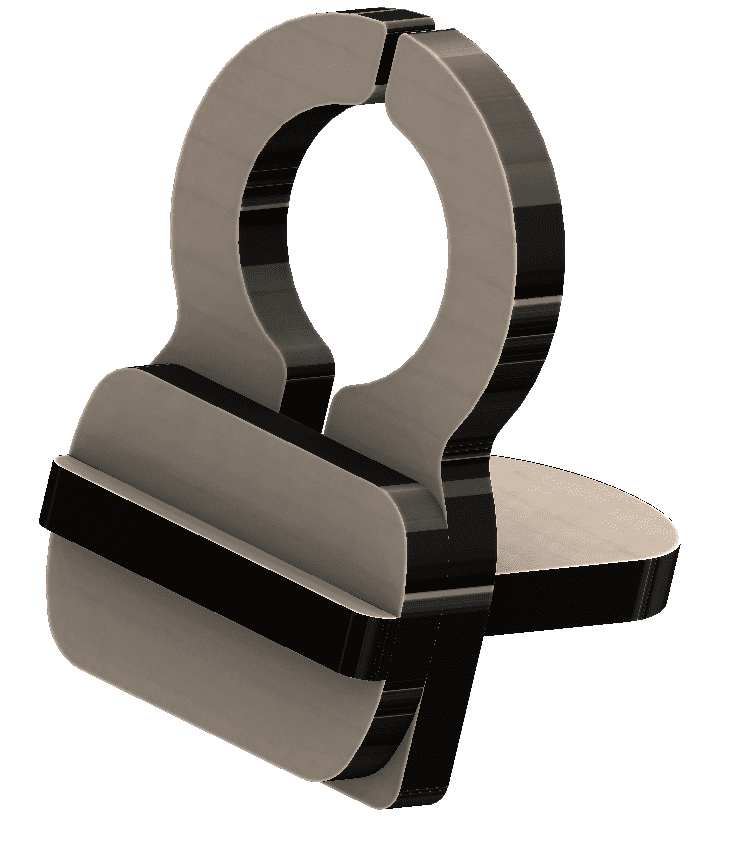

Laser cut wooden product.

For example, the wooden product on the right is a laser cut product where the back stand has to slide easily in both the main upright and adjustable ledge at the front.

Sheet plywood has a tolerance of ±0.5mm. When designing for nominal size it would mean the fit is very loose when the material is at the bottom limit and impossible to assemble when the material is at its top limit. Creating a cut file for 3 or 4 thicknesses between the top and bottom limits allows the operator to select the appropriate cut file for the material thickness.

To find out more about our design services, please contact us.

You must be logged in to post a comment.