Bespoke wooden Point of Sale stand

This wooden Point of Sale stand was designed for a client who sells oils at well-being events. This example demonstrates how we can help not only people who have an idea for a product, but also the people who are going to make the product. Adding value to your product without adding cost.

The design brief was very simple…

A Point of Sale (PoS) stand that can be flat packed, has 2 base tiers of identical size, a middle tier for a taller bottle, a top tier for a smaller bottle, and a removable sign for branding.

A nice easy project, but nothing is ever quite as simple as it first looks. We had identified that the best manufacturing process for the PoS stand was going to be laser cutting, and the most cost-effective material would be Birch Plywood. Plywood is notorious for having a very wide tolerance for thickness. ±0.5mm is standard. This wide tolerance makes it close to impossible to create a “one size fits all” design for anything that has parts that slide into each other.

This is where White horse CAD can add value to your product without adding cost. Because we research manufacturing processes and materials we know the limitations to design around. Laser cutting is an ideal example of this. Had we not spoken to the intended manufacturer we would not have known that we need to allow for the width of the laser (kerf) as well as the tolerance on the material if we want everything to slot together nicely. A stand that does not fit together is just as bad as one that fits together so easily it wobbles…

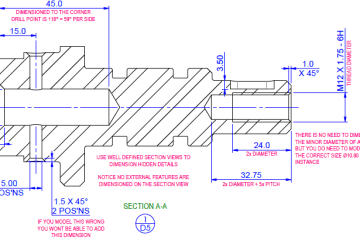

This is where an understanding of the process and materials and years of 3D CAD experience come into its own. We knew what basic thickness sheet we were going to use, and we knew the Kerf requirement. These were defined as global variables within SolidWorks.

These global variables allowed us to create a CAD model with manufacturing-based design intent. The fully parametric CAD model can easily be changed when the final thickness of the material the stand was being made from was known. Once the design had been approved by our client we spoke to the manufacturer again. This time asking them to measure the sheets of plywood they would be making the stand from with a digital caliper. We then input those values into the global variable table, updated the CAD model and created the 2D DXF files that would be used to cut the product.

This resulted in a stand that fits together beautifully and does not wobble or rock and a client who was very pleased with the results. Had we not understood the manufacturing process or the material tolerance issues. The stand would have been modeled at nominal size and the chances of it fitting together nicely would have been around 50/50 at best.

This resulted in a stand that fits together beautifully and does not wobble or rock and a client who was very pleased with the results. Had we not understood the manufacturing process or the material tolerance issues. The stand would have been modeled at nominal size and the chances of it fitting together nicely would have been around 50/50 at best.

White Horse CAD… we add value to your new products… not cost! To find out more, please contact us.

You must be logged in to post a comment.