This week’s Fun Friday Fact comes from the construction of the Golden Gate Bridge.

This week’s Fun Friday Fact comes from the construction of the Golden Gate Bridge.

The lead structural engineer named Joseph Strauss insisted on installing a safety net even though its $130,000 (£94,948.30) cost was deemed excessive. Over the four years of its construction, the net saved 19 men, who named themselves the “Halfway to Hell Club.”

This fact raises questions about the value of the net – the costs financially versus the safety of the workers, the impact of the net on project timescales, etc. The ‘Halfway to Hell Club’ is quite an extreme example of value given the life-or-death element. Still, it highlights numerous considerations when planning and delivering projects, also how values can be defined differently.

This fact raises questions about the value of the net – the costs financially versus the safety of the workers, the impact of the net on project timescales, etc. The ‘Halfway to Hell Club’ is quite an extreme example of value given the life-or-death element. Still, it highlights numerous considerations when planning and delivering projects, also how values can be defined differently.

What do our clients value? High-quality drawings, the rapid turnaround of prototypes, and great communication are some comments we’ve received. Our clients come back time after time, so, I’m confident we’re getting our value right, but it’s always at the forefront of my mind. Since my engineering career started in the mid-eighties, I’ve worked on many projects. I have experienced first-hand the urgency and eagerness to get projects completed. On-time delivery is essential for our clients to gain a competitive edge.

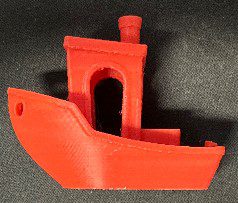

However, for me, value is relative to the end goal. Spending a little time creating high-quality, robust CAD models makes it easier to make iterative changes later in the design cycle. Once we have a robust part model, we can create an assembly of the parts, ensuring your product works as intended. Our in-house 3D printing capacity also makes it easier to have prototype parts in your hand.

Our design, prototype, and verification stages mean you can move forward to full-scale manufacture with confidence knowing your design meets or exceeds your requirements. 3D print prototyping is especially important when working with injection moulded parts; spending a relatively small amount on a few 3D prints is much better than realising a design problem after spending tens of thousands of pounds on an injection mould tool. We can bring value to your work. Please get in touch to find out more.

You must be logged in to post a comment.