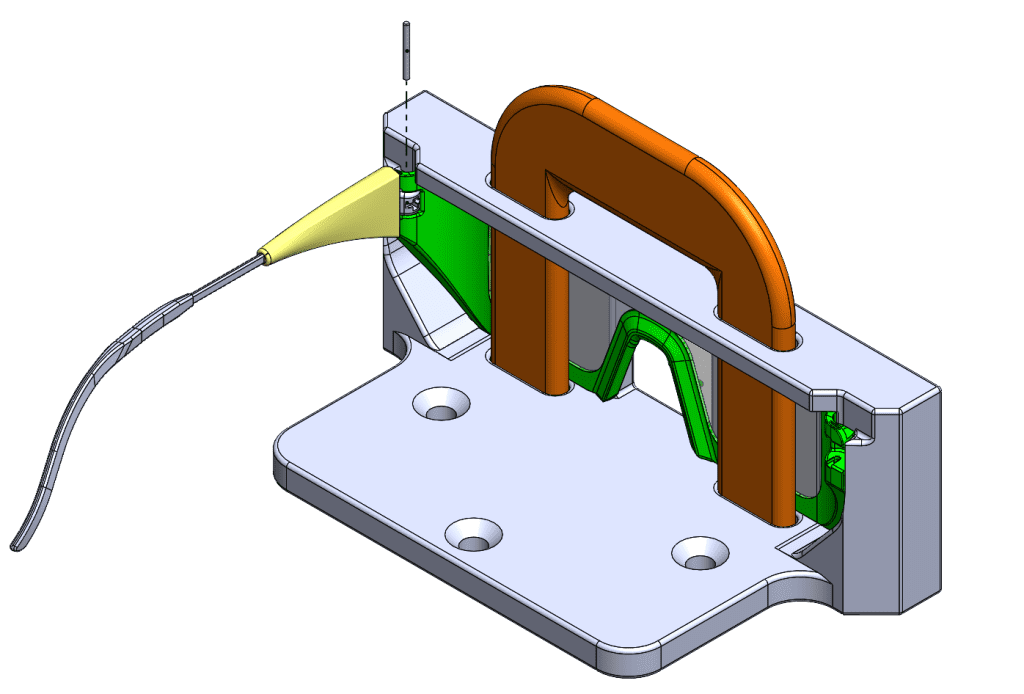

Have you ever been in a position where you are struggling to complete an assembly because you could use a third or even fourth hand? One of our clients had precisely this problem. Two parts to hold and a pin to introduce. We helped our clients solve this problem with some 3D printed tooling that holds one part securely, freeing up one hand to introduce the pin.

Have you ever been in a position where you are struggling to complete an assembly because you could use a third or even fourth hand? One of our clients had precisely this problem. Two parts to hold and a pin to introduce. We helped our clients solve this problem with some 3D printed tooling that holds one part securely, freeing up one hand to introduce the pin.

This is an excellent example of how White Horse CAD can help our clients solve problems and improve their workflow. We used the part model to design a simple 3D-printed fixture that matches and effectively supports the part’s geometry. This frees an operator’s hand to fit the retention pins easily and precisely without risking damage to the part or, more importantly, the operator.

Whilst 3D printing is not an ideal solution to all design problems, in this case, it is the most efficient and cost-effective way to create a simple fixture that aids assembly, keeps the operator safe and reduces the risk of damage to the products being assembled. This is a relatively low-cost solution to a problem that will improve product quality, reduce operator frustration and increase productivity.

If you would like more information on how 3D Printed Process Tooling can help solve your assembly nightmares, please contact us

or Find us on LinkedIn

You must be logged in to post a comment.